Niobium application projects are at an advanced stage

Taurus, a Strategic Defense Company and one of the world’s leading arms manufacturers, is developing relevant research into the application of new materials, such as Niobium.

A powerhouse in the production of various minerals, Brazil has more than 90% of the world’s reserves of this material, although it is still little explored for industrial and commercial purposes.

A pioneer with a strong investment in innovation, Taurus is working at an advanced stage on the development of an unprecedented weapon using Niobium in its composition, aimed at the armed and police forces of Brazil and the world.

In addition, the company is studying the inclusion of Niobium in the production of parts using Metal Injection Molding (MIM) technology, adding all the benefits of this new material, which guarantees greater resistance and durability.

The high-performance Metal Injection Molding technology allows Taurus to produce parts with complex geometry, at low cost and high volume, dispensing with the need for external suppliers, used by the majority of arms manufacturers, with a great advantage over traditional processes, such as micro-melting and machining. The current process combines the mechanical strength of metals with the shape versatility of polymers, starting with the injection of the components, with a subsequent thermal process to remove the polymers and sintering.

The study conducted by Taurus indicates that with just a small amount of Niobium, it is possible to modify the steel, making the alloy more efficient and the end product lighter and more resistant to temperatures, impacts and corrosion.

Niobium was initially used in incandescent lamp filaments. Today, its most common use is in medical devices, such as pacemakers, and in jewelry, as its metal alloys are physiologically inert and hypoallergenic.

When exposed to environmental conditions, Niobium forms a “protective” layer on the surface, preventing the metal from oxidizing. Being highly resistant to corrosion, Niobium’s added resistance to metal alloys makes it an excellent choice of raw material for making automotive and aerospace parts. It also has a high melting point, ideal for tools and equipment that work at high temperatures or with combustion processes.

The company’s research into graphene is at an even more advanced stage. Taurus currently has more than 10 products in its portfolio made from the material.

Cerakote Graphene robotic paint cell for the surface treatment of parts: Together with Cerakote®, Taurus has developed a special paint with graphene in its composition, which protects and makes weapons more resistant to scratches and other damage to equipment.

Pistol line: In 2022, the company launched the world’s first gun with graphene in the composition of its injected components and in the surface treatment of metal parts, the GX4 Graphene pistol, revolutionizing the market, marking the beginning of the 3rd generation of pistols and making Brazil a pioneer in this innovation. And it has continued to innovate. Today, it offers several models on different pistol platforms: the GX4 family (GX4 Graphene, GX4 XL Graphene and GX4 Carry Graphene), the Striker TS9 platform (TS9 Graphene and the compact TS9c Graphene version) and the Taurus Hammer platform (TH380 Graphene and the compact TH380c Graphene version).

Holsters: Taurus has also created a model of holster with graphene in its composition for the GX4 T.O.R.O. Graphene pistol, which offers safety and durability, with resistance to impacts, a shape that remains unchanged and a surface that does not accumulate moisture. In addition, its ergonomic design provides a perfect fit close to the body, with rounded, smooth and polished edges, and a recessed trigger guard for quick access to the trigger.

Carry cases: Unique graphene-coated carry cases have also been developed.

Line of suppressors: In April 2023, it launched its line of high-performance, multi-caliber suppressors (or silencers), aimed at improving the performance of tactical and special operations professionals. Taurus suppressors are the first in the world to be manufactured with a unique Titanium core, with an exclusive Cerakote® Graphene coating and innovative ring systems.

Gun lubricant: In June 2023, the company launched the UP1 TAURUS gun lubricant, with the exclusive TN-M technology (nanotechnological treatment of metals), whose chemical composition includes Graphene, a component which, among other things, contributes to the preservation and conservation of the gun’s movable and fixed metal parts, guaranteeing better maintenance and lubrication.

Line of handmade knives: Taurus also recently launched a collection of handmade knives, including the world’s first knife with a Cerakote Graphene blade finish.

Taurus is also developing other pioneering projects, taking into account the new technological cycle of unprecedented materials used in the manufacture of weapons, such as DLC (Diamond Like Carbon) and Long Fiber Polymer, adding increasingly lighter and more resistant weapons to its portfolio.

“The right choice and development of materials for each application are fundamental to obtaining high-performance products. We are committed to developing solutions that combine quality, competitiveness, innovation and sustainability. We invest in people skills, new products, processes and cutting-edge technologies, both in terms of equipment and materials, to guarantee the excellence of our products and meet our customers’ expectations. The development of new materials is an essential factor in stimulating innovation,” says Salesio Nuhs, Global CEO of Taurus.

Since 2020, Taurus has had the Brazil/United States Integrated Technology and Engineering Center (CITE) in Brazil, with more than 250 engineers dedicated to research and development of new products, technologies and processes.

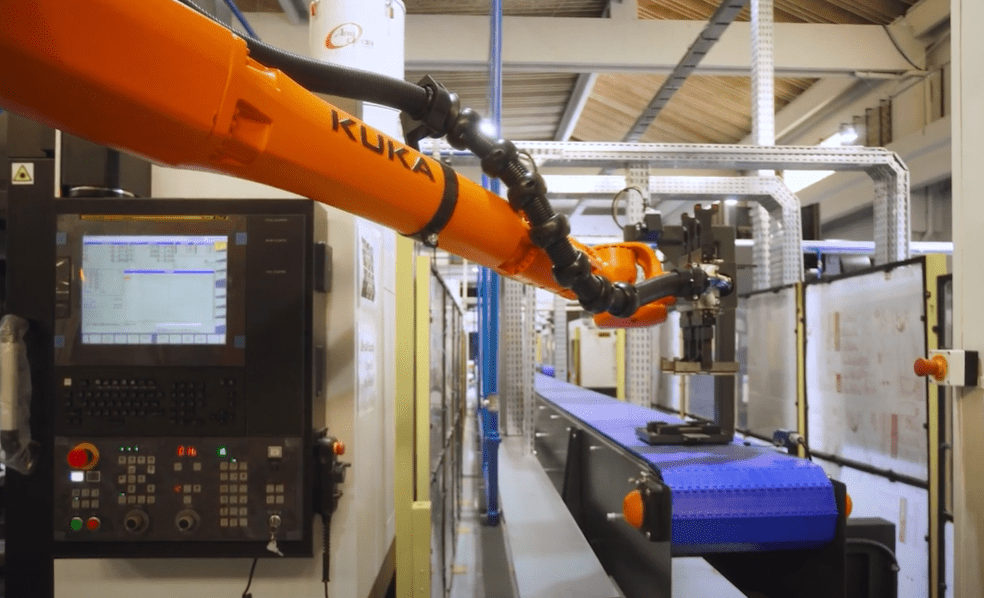

In recent years, the company has also established strategic partnerships with universities, laboratories and research institutes that work in line with the most advanced technological solutions in the world, with the aim of expanding its research and development capacity. It has also invested more than R$500 million in new machinery, equipment, systems, automated production processes and the development of robotic cells, in order to modernize its industrial park towards Industry 4.0.

At the same time, the company is committed to the continuous training and development of people, with the aim of contributing effectively to the personal and professional growth of its employees, and to playing an active role in the development and use of technology, adopting efficient and robust operational processes. In this context, it has the Taurus Continuing Education Program, which includes a training platform for the professional qualification of its entire operation, as well as incentives for employees to qualify for undergraduate, master’s and doctoral courses at renowned educational institutions.

In addition, Taurus is focused on developing products that are compatible with the needs of the future, in line with ESG (environmental, social and corporate governance) concepts. In this sense, the company is committed to fostering pioneering projects, such as those mentioned above, which promote new sustainable materials and applications that add value to Brazil’s natural wealth. Because they are disruptive technologies, they tend to compete with existing technologies and replace materials that have been used for decades.

“We are a Brazilian company and, not least for this reason, we believe that these investments and projects are extremely important for the country, adding value to our wealth, as we have 75% of the planet’s graphite reserves and more than 90% of its niobium reserves, promoting technological progress and contributing to sustainability. These initiatives pave the way for the research and manufacture of much more modern and technological products,” says Nuhs.

The defense industry plays an important role in national security, in the economy and in supporting and developing new technologies. The world’s main technologies came from the defense area and then permeated into society, such as the internet, which was created in the middle of the Cold War for strictly military purposes, and the microwave, which came about thanks to military engineering.