The role of engineers in increasing the technological independence of Brazil’s Naval Power

By 1T (RM2-T) Daniela Meireles

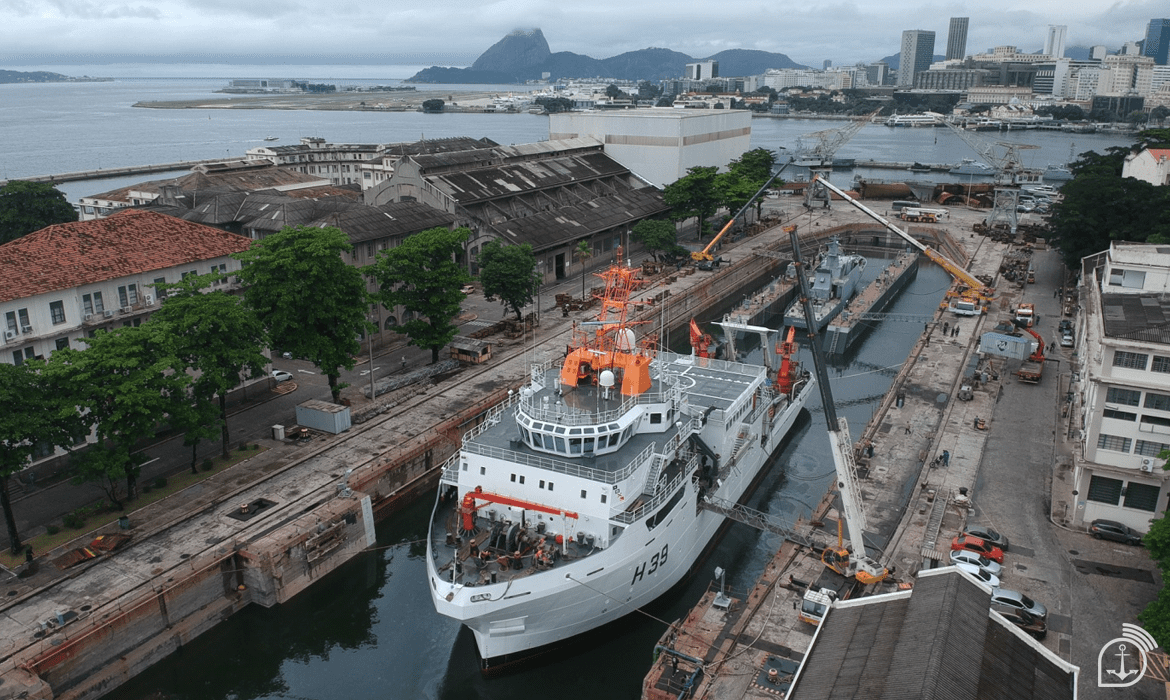

After sailing for six months in the Southern Ocean, whose waters often reach sub-zero temperatures, the Oceanographic Support Vessels “Ary Rongel” and the Polar “Almirante Maximiano” are back in Brazil, where they are resting in the warm climate. Not just any ship can withstand variations of this magnitude. Just like the hulls, the systems need to withstand and continue to function, regardless of the climate to which they are subjected. This is just one of the many challenges the Navy’s engineers have to deal with.

“On-board equipment must meet much more stringent requirements in order to continue operating after suffering severe impacts. Ships must continue to fight even after being hit by cannon or missile fire. They also have to operate in a wide temperature range, such as polar ships, which operate in temperatures well below zero, and also in the summer in Rio de Janeiro,” explains the Director of the Navy’s Systems Maintenance Center (CMS), Captain Rafael Dutra.

Many engineering fronts are involved in ensuring that a single ship is capable of responding to so many demands. Today, the Navy’s Corps of Engineers has professionals in at least 16 areas, not only for building and maintaining infrastructure, but also for systems such as propulsion, armaments and computing. These specialists are distributed among military organizations with different purposes, such as those dedicated to ship maintenance, research and technology development and the creation of technical guidelines and standards.

With an eye on the future

Each one contributes in some way to Brazil’s ability to keep up with global technological advances necessary for its defense. “The complexity of threats is increasing exponentially and technology is constantly evolving. Keeping up to date is very important to bring the most appropriate solutions to the Navy’s challenges, such as improving the protection of automated command and control systems used by modern military platforms, which work with information in real time and cannot rely on antivirus, so other means of cyber defense have to be employed,” says the CMS Director.

In addition to cyber defense, the Navy’s engineers are also working on the development of Brazil’s first conventionally nuclear-powered submarine. Currently, only the United States, the United Kingdom, Russia, France and China have this technology. “The Navy Corps of Engineers works to design, build and operate the nuclear power plant, as well as mastering the fuel cycle. It’s a complex project, mastered by only a few countries, and it will place Brazil in this select group,” says Captain Rafael Dutra.

Without losing sight of the future challenges of shipbuilding, these professionals also have to deal with the adversities of the present, such as obsolescence. “The life cycle of a ship is expected to be around four decades. But there are ships in operation with much longer service lives, such as the Monitor “Parnaíba”, built at the Navy Arsenal and incorporated in 1938. It is the oldest warship in the world in military service. The engineers are still working on repairs to the cannons, systems and engines,” says the Director.

The knowledge and experience combined result in products that are not only applied to national defense, but also bear fruit in areas such as health. According to the expert, the Navy’s research into the development of nuclear energy has generated “technological drag”. One example is the production of radioisotopes, which can be used to make medicines to treat heart, cancer, hematological and neurological diseases.

The benefits for society can also be seen in professional training. The Naval and Oceanic Engineering Course, created more than 50 years ago by the Navy in partnership with the University of São Paulo, for the graduation of Naval School Aspirants who choose this career, is not exclusive to the military. “The agreement was also positive for the civilian sector, contributing to the growth of the Brazilian naval industry,” says Sea and War Captain Rafael Dutra.

Unlike the other Single Forces, the Navy does not have its own educational institution for engineers. The model adopted by the Naval Force is, according to the Director of the Navy’s Systems Maintenance Center, the same as that adopted in countries such as the United States, which has a partnership with the Michigan Institute of Technology (MIT), and the United Kingdom, with King’s College. This qualified workforce in the country is even more important in the face of restrictions on the international military market for the purchase of specific means and equipment.

The need for local production, through the Defense Industrial Base, created a shortage of engineers and the number of graduates from the partnership with the University of São Paulo (USP) was no longer sufficient to meet the Navy’s needs. “You can clearly see this movement from the shipbuilding boom in the 1970s, when engineers were recruited from the domestic market through special contracts, mainly for the construction of the ‘Niterói’ class frigates,” he explains.

Today, the Navy Corps of Engineers accepts both forms of entry: both training via the Naval School and the public competition for engineers trained in civilian institutions. The latter has been published, with applications starting on April 30, to fill 24 vacancies in different areas, such as Naval, Civil, Nuclear, Chemical, Mechanical and Electrical Engineering. The stages include objective and discursive tests of professional knowledge, writing and translation of technical English texts.

*** Translated by DEFCONPress FYI Team ***